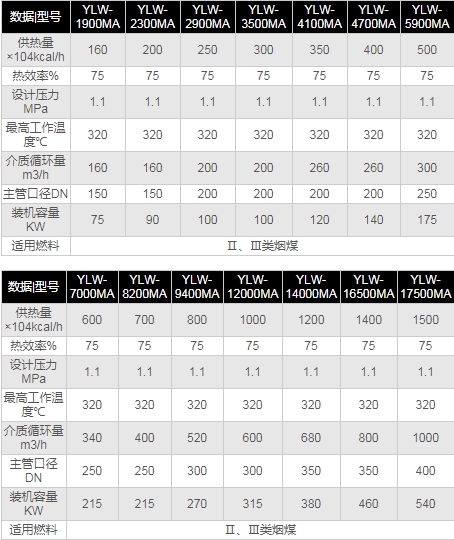

供熱量:(160-2000)×104Kcal/h,設計壓力:1.1MPa

YLW系列有機熱載體爐為組裝式強制循環鏈條爐排鍋爐。鍋爐本體前部為爐膛輻射受熱面,由密排的雙方形盤管構成;后部為對流沖刷受熱面,由蛇形管束組成。鍋爐由上部本體和下部鏈條爐排組成,工地現場組合。空氣預熱器布置在鍋爐后面。燃燒生成的高溫煙氣在爐膛被吸走部分熱量,經轉向煙室進入對流受熱面換熱,出鍋爐后在空氣預熱器中加熱鍋爐燃燒所需的空氣,再經除塵器由引風機將煙氣送至煙囪排入大氣。

安裝方便,只要上部本體和下部排爐合攏即可,安裝周期短。

爐膛采用雙密排盤管,受熱面布置充足,降低管子表面熱負荷,是導熱油使用更an全。

介質流程合理,導熱油由低(進口)到高(出口),運行中產生的氣體很難在爐內停留,可方便的排出系統。

爐拱設計合理,煙氣在爐膛內停留時間長,燃燒更充分。

轉向煙室布置受熱面,使隔墻避免高溫煙氣直接沖刷,有效防止隔煙墻脫落產

Heat supply: (160-2000) × 104Kcal / h, design pressure: 1.1MPa

YLW series of organic heat carrier furnace for the assembly of forced circulation chain grate boilers. The front of the boiler body is the radiant heating surface of the furnace, which is formed by the double square coil of the close-packed row; the back is the heating surface of convection flushing and is composed of the serpentine tube bundle. Boiler by the upper body and the lower part of the chain grate composition, the site site portfolio. The air preheater is arranged behind the boiler. The high-temperature flue gas generated by the combustion is sucked away in the hearth and transferred to the convection heating surface through the turning smoke chamber. After exiting the boiler, the air required for the combustion of the boiler is heated in the air preheater, which is then passed through the dust collector by the induced draft fan. The smoke is sent to the chimney and discharged into the atmosphere.

Easy to install, as long as the upper body and the lower row of furnace can be closed, the installation cycle is short.

Furnace with double dense row coil, heating surface layout sufficient to reduce the heat load on the pipe surface, is the use of thermal oil more secure.

The medium flow is reasonable, and the heat transfer oil is low (inlet) to high (outlet). The gas generated during operation is difficult to stay in the furnace and can be easily discharged.

Furnace arch design is reasonable, flue gas residence in the furnace for a long time, burning more fully.

Steering smoke chamber layout heated surface, so that the wall to avoid direct erosion of high-temperature flue gas, which effectively prevent the separation of cigarette wall off