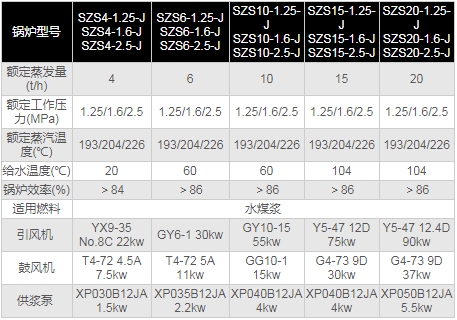

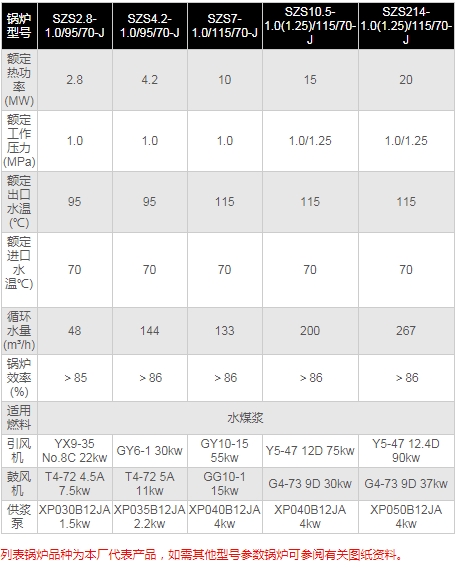

產品范圍

蒸發量:2-35t/h,設計壓力:0.7-2.5MPa

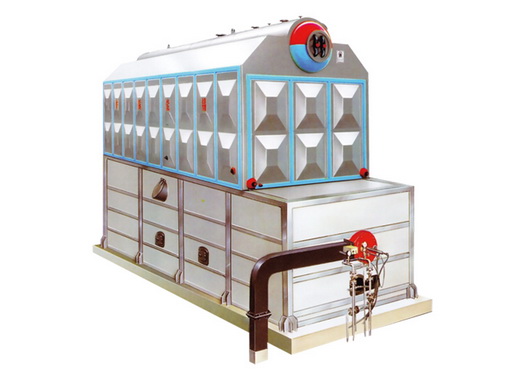

錫能SZS型系列水煤漿蒸汽、熱水鍋爐是新一代環保產品。具有燃料成本低和污染物排放低的特點,是燃油、燃煤鍋爐的替代產品。該系列鍋爐為自然循環、室燃水管蒸汽鍋爐,微負壓燃燒,平衡通風。本體采用縱向布置得上、下兩只鍋筒,燃燒器布置在前墻,水煤漿在爐膛內充分燃燒(燃燒效率>98%),產生的高溫煙氣經爐膛出口橫向沖刷對流管束,再經布置在鍋爐后部的空氣預熱器換熱,通過脫硫除塵器的處理,然后由引風機將煙氣送至煙囪排入大氣。

水煤漿燃燒效率(>98%),鍋爐設計熱效率高(接近90%);

排放符合國家《鍋爐大氣污染物排放標準》一類地區環保要求;

采用前置穩燃爐膛結構和合理的爐膛截面、容積,使產品能適應多種水煤漿的燃燒,并有效控制爐膛的結焦現象。

Product Range

Evaporation capacity: 2-35t/h, design pressure: 0.7-2.5MPa

Tin to SZS Series CWM steam, hot water boiler is a new generation of environmentally friendly products. With low fuel costs and low emissions of pollutants, fuel, coal-fired boiler is the best alternative. The series of boilers for natural circulation, room steam pipe steam boiler, micro-negative pressure combustion, balanced ventilation. The body is arranged longitudinally with two lower drums. The burner is arranged on the front wall and the coal-water slurry is fully burned in the furnace (combustion efficiency> 98%). The generated high-temperature flue gas scours the convection tube bundle laterally through the furnace outlet. The air preheater arranged at the back of the boiler exchanges heat and is treated by the desulfurization precipitator. Finally, the induced draft fan sends the flue gas to the chimney to discharge into the atmosphere.

CWS combustion efficiency (> 98%), boiler design thermal efficiency (nearly 90%);

Emissions comply with the requirements of the State Environmental Protection Standard for Emission Standards of Air Pollutants for Boilers;

Pre-stabilizing furnace chamber structure and a reasonable cross-section of the furnace, the volume, so that the product can adapt to a variety of coal-water slurry combustion, and effectively control the furnace coke phenomenon.